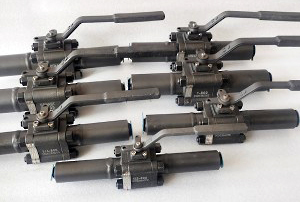

Amavalvu ebhola lensimbi ahlanganisiweziyimikhiqizo yama-valve esetshenziswa kabanzi ezimbonini eziningi. Ngenxa yokusebenza kwayo okuhle kakhulu, isetshenziswa kabanzi ezinhlotsheni ezahlukene zoketshezi njengomoya, amanzi, umusi, izinto ezahlukahlukene ezibolile, udaka, uwoyela, insimbi ewuketshezi kanye nezinto ezikhipha imisebe. Kodwa uyazi ukuthi ziyini izinzuzo zama-valve ebhola ensimbi eqinisiwe? Ake ngikunikeze isingeniso esifushane.

1. Ukumelana okunamandla ne-vulcanization kanye nokuqhekeka. Izinto zokwakhai-valve yebhola yensimbi eyenziwe ngobumbaUma uthintana ne-medium kukhona izinto zobuchwepheshe obuphezulu, ezihambisana nezinga elijwayelekile lamazwe ngamazwe. Ubuso bumbozwe nge-nickel, obungahlangabezana nokusebenza kwe-vulcanization ephezulu.

2. I-valve yensimbi eyenziwe ngensimbi yenziwe ngezinto ze-polymer noma i-alloy, emelana nokushisa okuphezulu kanye nomfutho ophezulu, futhi ifanelekela ukudluliselwa kanye nokugoba kwemidiya ehlukahlukene. Ngaphezu kwalokho, ngenxa yezinto ezikhethekile, inokumelana okunamandla kokugqwala, ihlala isikhathi eside kanye nobubanzi bokusetshenziswa kwayo.

3. Akuyona nje kuphela ivalvu eyenziwe ngezinto ezingagqwali, ngisho nesihlalo sevalvu senziwe ngezinto ezikhethekile, futhi le nto iyi-PTFE engangeni cishe kuwo wonke amakhemikhali, ngakho ingahlala ivaliwe isikhathi eside. Ngenxa yokungangeni kwayo okuqinile, isebenza kahle, akulula ukuguga, futhi ingasetshenziswa isikhathi eside.

4. Ngokuvamile,i-valve yebhola yensimbi eyenziwe ngobumbailingana ngokulinganayo, ngakho-ke ingamelana nokucindezela okukhulu kwepayipi, futhi indawo yayo akulula ukuyishintsha. Isebenze kahle kungakhathaliseki ukuthi ivulekile ngokuphelele noma ivulekile kancane. Ukusebenza kahle kokuvala futhi ngeke inamathele lapho kuthuthwa uketshezi oluqinile.

Lokhu okungenhla kungenye yezimpawu zamavalvu ebhola ensimbi ahlanganisiwe. Nakuba kungezona zonke izici ezibalwe ngenhla, labo abasembonini bayazi ukuthi leli yivalvu esebenza kahle. Uma inkampani esebenzisa ukuthutha okuwuketshezi nayo idinga ukufaka ivalvu, ingacatshangelwa.

Isikhathi sokuthunyelwe: Ephreli-30-2022