1. Incazelo yohlobo lokupakisha lwe-Graphite

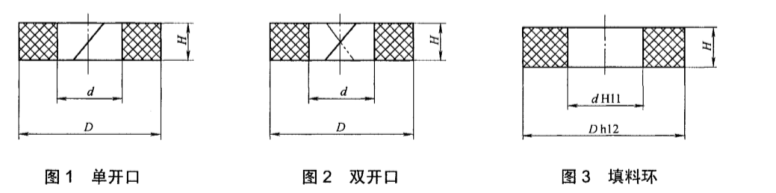

Kunezinhlobo ezintathu ezilandelayo zama-filler ezivame ukusetshenziswa ku-amavalvu

Ukupakisha okusetshenziswe kulo msebenzi uhlobo lokuvula okukodwa kuMfanekiso 1 kanye nokupakisha okumise okwendandatho kuMfanekiso 3. Izithombe zangempela zimi kanje:

Umfanekiso 1 Ukupakisha uhlobo lokuvula okukodwa

Umfanekiso 3 Ukupakisha indandatho yokupakisha

Imisebenzi yokusetshenziswa kwalezi ziphakeji ezimbili ezingenhla iyafana, umehluko usezimweni ezahlukene zokusetshenziswa. Ukupakisha okuvula kanye kufanelekile ukufaka esikhundleni sokupakisha ngesikhathi sokulungiswa kwamavalvu nsuku zonke. Ukupakisha kungashintshwa ku-inthanethi, futhi ukupakisha kwendandatho yokupakisha kufanelekile ukulungisa kabusha ivalvu. Kusetshenziselwa ukuqaqa nokulungisa.

2. Incazelo yezimpawu zokupakisha ze-graphite

Ngokwezidingo zobuchwepheshe zokukhiqiza izigcwalisi, isigcwalisi sidinga ukuba nesilinganiso esithile sokuqina, ngakho-ke kuzoba nokuqina kusukela ngaphakathi kuya ngaphandle ngemva kokwakheka kokugcwaliswa. Izinhlobo ezimbili ezishiwo ngenhla zezigcwalisi ze-graphite zohlobo olulodwa ziyizigcwalisi ezilukiwe inqubo yazo yokubumba ilukiwe ngemicu eminingi ye-graphite, futhi ukuqina kudonswa yigebe elilukiwe futhi akukho mkhondo ocacile wokulangazelela ukwanda. I-graphite yokupakisha yohlobo lwendandatho yokupakisha iyisigcwalisi esincane esinongaphakathi oluncane. Ngemva kwesikhathi eside sokuma, ukuqina kwangaphakathi kuzobonisa imifantu ebusweni bokupakisha futhi kukhulule le ngxenye yokucindezeleka. Lolu hlobo lokugcwalisa luzohlala luzinzile futhi lungashintshi ngemva kokuvela komfantu othile. Uma lucindezelwa futhi, umfantu uyanyamalala futhi izinga lokubuyela emuva lihlangabezana nesidingo.

Okulandelayo yizidingo zobuchwepheshe zamasongo e-graphite aguquguqukayo

Ithebula 2 Ukusebenza kwendandatho yokupakisha

| ukusebenza | iyunithi | inkomba | ||

| I-graphite eguquguqukayo eyodwa | Inhlanganisela yensimbi | |||

| uphawu | g/cm³ | 1.4~1.7 | ≥1.7 | |

| Isilinganiso sokucindezela | % | 10~25 | 7~20 | |

| Izinga lokubuya | % | ≥35 | ≥35 | |

| Ukulahlekelwa isisindo okushisayo | 450℃ | % | ≤0.8 | —- |

| 600℃ | % | ≤8.0 | ≤6.0 | |

| Isilinganiso sokungqubuzana | —- | ≤0.14 | ≤0.14 | |

| a Kuma-composite ensimbi, lapho iphuzu lokuncibilika kwensimbi liphansi kunezinga lokushisa lokuhlola, lokhu kuhlolwa kokushisa akufaneleki. | ||||

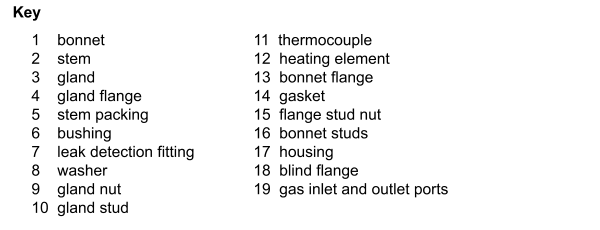

3. Mayelana nokusetshenziswa kokupakisha i-graphite

Ukupakisha kwe-graphite kusetshenziswa esikhaleni esivaliwe phakathi kwesiqu se-valve kanye ne-packing gland, futhi ukupakisha kusesimweni sokucindezelwa ngesikhathi sokusebenza. Kungakhathaliseki ukuthi ukupakisha kohlobo olulodwa noma ukupakisha kohlobo lwendandatho yokupakisha, akukho mehluko emsebenzini wesimo sokucindezelwa.

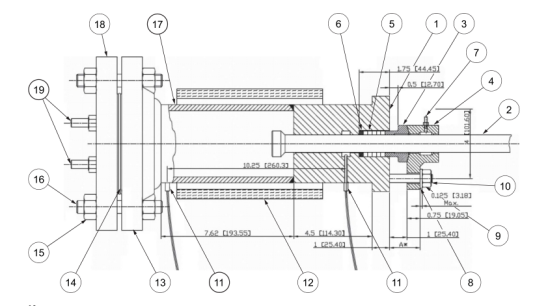

Okulandelayo umdwebo wesimo sokusebenza kokupakisha (umfanekiso wokuhlolwa kophawu lokupakisha)

Isikhathi sokuthunyelwe: Julayi-12-2021