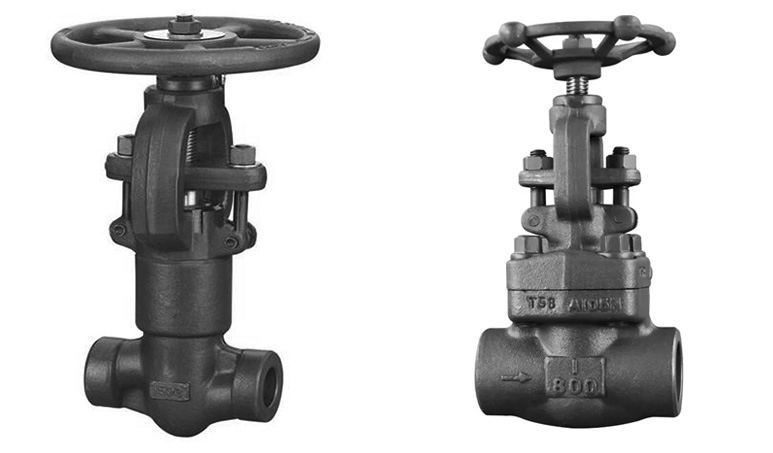

Amavalvu embulunga yensimbi eyakhiwezihlukaniswe ngezigabaamavalvu embulunga yensimbi yekhabhoni eyenziwe ngobumbafuthiamavalvu embulunga yensimbi engagqwali eyenziwe ngobumba, evame ukusetshenziswa ezikhathini zokucindezela okuphezulu nokuphakathi (150lb-800lb, 1500LB, 2500LB), kanye nezikhathi zokushisa okuphezulu nokuphansi (-196℃ ~ 700℃), amavalvu ensimbi ahlanganisiwe anamandla aphezulu kanye nezakhiwo ezingcono zemishini ukuze ahlangabezane nezidingo zokucindezela okuphezulu. Kodwa kunqunyelwe enkambisweni yokubopha, kuvame ukusebenza kuphela kusayizi omncane nophakathi (1/2 “, 3/4 “, 1 “, 1-1/4 “, 1-1/2 “, 2, 2-1/2 “, 3 “kanye no-4”.

Ukusebenza kweValve kungaba ngesandla, igiya le-bevel, i-actuator yomoya, i-actuator kagesi, i-actuator yomoya, i-pneumatic-hydraulic, i-electro-hydraulic.

Izinzuzo zesakhiwo se-valve yensimbi eyakhiwe

1. I-valve yensimbi eyakhiwe isebenzisa uphawu oluziqinisayo lokucindezela, futhi zombili iziphetho zepayipi legatsha lomzimba we-valve ziyashintshwa.

2. Isihlalo se-valve yensimbi eyakhiwe, indawo yokuvala idiski ye-valve yenziwe nge-cobalt-based cemented carbide plasma spray welding, ukumelana nokuguguleka, ukumelana nokuhuzuka okuphezulu.

3. Isiqu se-valve siphathwa nge-nitriding yokumelana nokugqwala, enokumelana okuhle nokugqwala kanye nokumelana nokuhuzuka.

4 enkambisweni yokuvula nokuvala, ngenxa yediski ye-valve emzimbeni we-valve, ukungqubuzana kobuso kuncane, futhi ukumelana nokuguguleka kuncane.

5. Ngokuvamile kukhona ubuso obubodwa bokuvala emzimbeni we-valve kanye ne-disc, ngakho-ke inqubo yokukhiqiza ingcono futhi ilungele ukulungiswa

Ivalvu kumele ihlolwe ngaphambi kokufakwa, futhi indinganiso yokuklama ivalvu kufanele ihambisane ne-API 602 yamanje yamazwe ngamazwe. Ukuhlolwa kokusebenza kwamandla nokuqina kufanele kwenziwe ngaphambi kokufakwa.

Ekuhlolweni kwamandla, ingcindezi yokuhlola iphindwe ka-1.5 kunengcindezi evamile, futhi ubude bayo bungaphansi kwemizuzu emi-5.

Igobolondo le-valve kanye nokuvalwa kwesihlalo sangemuva kufanele kuqinisekiswe ngaphandle kokuvuza.

Ukuhlolwa kokuvala, ingcindezi yokuhlola iyizikhathi eziyi-1.1 zengcindezi evamile;

Ingcindezi yokuhlola esikhathini sokuhlolwa kufanele ihlangabezane nezidingo ze-API 598 standard, ngaphandle kokuvuza ebusweni bokuvala idiski njengoba kufanele.

Isikhathi sokuthunyelwe: Agasti-20-2021