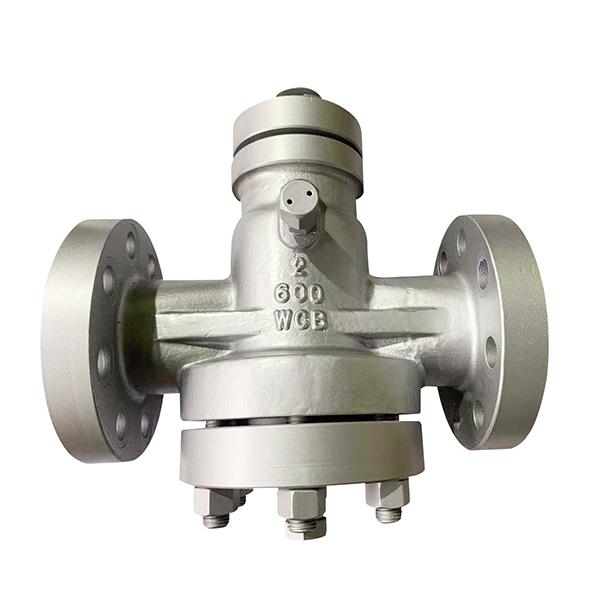

WCB CLASS 600 PLUG VALVE

WCB CLASS 600 PLUG VALVE RTJ/RF End

Key works: WCB, FLANGE, plug, valve, sleeved, ptfe, seat, class 600, class 300, 5A, 6A

PRODUCT RANGE:

Sizes: NPS 2 to NPS 24

Pressure Range: Class 150, 300, Class 600, 900, 1500lb

Flange Connection: RF, FF, RTJ

MATERIALS:

Casting: UB6,(A216 WCB, A351 CF3, CF8, CF3M, CF8M, A995 4A, 5A, A352 LCB, LCC, LC2) Monel, Inconel, Hastelloy

STANDARD

| Design & manufacture | API 599, API 6D, ASME B16.34 |

| Face-to-face | ASME B16.10,EN 558-1 |

| End Connection | ASME B16.5, ASME B16.47, MSS SP-44 (NPS 22 Only) |

| - Socket Weld Ends to ASME B16.11 | |

| - Butt Weld Ends to ASME B16.25 | |

| - Screwed Ends to ANSI/ASME B1.20.1 | |

| Test & inspection | API 598, API 6D,DIN3230 |

| Fire safe design | API 6FA, API 607 |

| Also available per | NACE MR-0175, NACE MR-0103, ISO 15848 |

| Other | PMI, UT, RT, PT, MT |

Design Features:

1. Sleeve type soft sealing plug valve sealing is done by the sealing surface around the card sets, the unique 360 ° metal lip protection fixed card sets;

2. The valve has no cavity to accumulate the media;

3. The metal lip provides the self-cleaning function in the spinning process, which is suitable for the viscous and easily fouling conditions;

4. Two-way flow, it is more convenient to use installation;

5. The material and flange dimensions of the parts can be selected according to the actual working conditions or users’ requirements, and meet all kinds of engineering needs.

Newsway Valve company plug valve is a rotary valve with a closing piece or a plunger. By rotating 90 degrees, the channel port on the valve plug is communicated or separated with the channel port on the valve body to realize opening or closing.

Its valve plug can be cylindrical or conical. In cylindrical valve plugs, the channels are generally rectangular; in conical valve plugs, the channels are trapezoidal. These shapes make the structure of the plug valve lighter. It is most suitable as a cut-off and connection medium and shunt, but depending on the applicable properties and the erosion resistance of the sealing surface, it can sometimes be used for throttling.

The plug valves are classified according to the use: soft seal plug valves, oil lubricated hard seal plug valves, lift plug valves, three-way and four-way plug valves.

Soft-sealed plug valves are often used in harsh environments such as corrosive, highly toxic and high-hazardous media, where leakage is strictly prohibited, and where the valve material does not pollute the media. The valve body can be selected from carbon steel, alloy steel and stainless steel according to the working medium.

Lubricated hard seal plug valves can be divided into conventional oil lubricated plug valves and pressure balanced plug valves. Special grease is injected from the top of the plug body between the cone hole of the valve body and the plug body to form an oil film to reduce the opening and closing torque of the valve and improve the sealing performance and service life. The working pressure can reach 64MPa, the maximum working temperature can reach 325 degrees, and the maximum diameter can reach 600mm.

Lifting plug valves have various structural forms. When the valve is opened, the plug is raised, and the plug is rotated 90 degrees to the full opening of the valve to reduce the friction with the sealing surface of the valve body; when the valve is closed, the plug is rotated 90 degrees to the closed position. Drop to contact the sealing surface of the valve body to achieve sealing.

Three-way and four-way stopcocks are suitable for changing medium flow direction or for medium distribution. According to the requirements of the working conditions, you can choose soft sealing bushing or soft sealing, hard sealing lift plug valve.

If you need more details about valves please contact NSW(newsway valve) sales department

Materials of Newsway Valve Manufacturer Products

The China Valve Manufacturer from China, its valves body and trim material can be offered in Forged type and Casting type. Next to Stainless Steel and Carbon Steel material, we also manufacture valves in special materials such as titanium, nickel alloys, HASTELLOY®*, INCOLOY®, MONEL®, Alloy 20, super-duplex, corrosion resistant alloys and urea grade materials.

Available Valve Materials

| Tradename | UNS nr. | Werkstoff nr. | Forging | Casting |

| Carbon steel | K30504 | 1.0402 | A105 | A216 WCB |

| Carbon steel | 1.046 | A105N | ||

| Low Temp Carbon steel | K03011 | 1.0508 | A350 LF2 | A352 LCB |

| High Yield steel | K03014 | A694 F60 | ||

| 3 1/2 Nickel steel | K32025 | 1.5639 | A350 LF3 | A352 LC3 |

| 5 Chrome, 1/2 Moly | K41545 | 1.7362 | A182 F5 | A217 C5 |

| 1 1/4 Chrome, 1/2 Moly | K11572 | 1.7733 | A182 F11 | A217 WC6 |

| K11597 | 1.7335 | |||

| 2 1/4 Chrome, 1/2 Moly | K21590 | 1.738 | A182 F22 | A217 WC9 |

| 9 Chrome, 1 Moly | K90941 | 1.7386 | A182 F9 | A217 CW6 |

| X 12 Chrome, 091 Moly | K91560 | 1.4903 | A182 F91 | A217 C12 |

| 13 Chrome | S41000 | A182 F6A | A351 CA15 | |

| 17-4PH | S17400 | 1.4542 | A564 630 | |

| 254 SMo | S31254 | 1.4547 | A182 F44 | A351 CK3MCuN |

| 304 | S30400 | 1.4301 | A182 F304 | A351 CF8 |

| 304L | S30403 | 1.4306 | A182 F304L | A351 CF3 |

| 310S | S31008 | 1.4845 | A182 F310S | A351 CK20 |

| 316 | S31600 | 1.4401 | A182 F316 | A351 CF8M |

| S31600 | 1.4436 | |||

| 316L | S31603 | 1.4404 | A182 F316L | A351 CF3M |

| 316Ti | S31635 | 1.4571 | A182 F316Ti | |

| 317L | S31703 | 1.4438 | A182 F317L | A351CG8M |

| 321 | S32100 | 1.4541 | A182 F321 | |

| 321H | S32109 | 1.4878 | A182 F321H | |

| 347 | S34700 | 1.455 | A182 F347 | A351 CF8C |

| 347H | S34709 | 1.4961 | A182 F347H | |

| 410 | S41000 | 1.4006 | A182 F410 | |

| 904L | N08904 | 1.4539 | A182 F904L | |

| Carpenter 20 | N08020 | 2.466 | B462 N08020 | A351 CN7M |

| Duplex 4462 | S31803 | 1.4462 | A182 F51 | A890 Gr 4A |

| SAF 2507 | S32750 | 1.4469 | A182 F53 | A890 Gr 6A |

| Zeron 100 | S32760 | 1.4501 | A182 F55 | A351 GR CD3MWCuN |

| Ferralium® 255 | S32550 | 1.4507 | A182 F61 | |

| Nicrofer 5923 hMo | N06059 | 2.4605 | B462 N06059 | |

| Nickel 200 | N02200 | 2.4066 | B564 N02200 | |

| Nickel 201 | N02201 | 2.4068 | B564 N02201 | |

| Monel® 400 | N04400 | 2.436 | B564 N04400 | A494 M35-1 |

| Monel® K500 | N05500 | 2.4375 | B865 N05500 | |

| Incoloy® 800 | N08800 | 1.4876 | B564 N08800 | |

| Incoloy® 800H | N08810 | 1.4958 | B564 N08810 | |

| Incoloy® 800HT | N08811 | 1.4959 | B564 N08811 | |

| Incoloy® 825 | N08825 | 2.4858 | B564 N08825 | |

| Inconel® 600 | N06600 | 2.4816 | B564 N06600 | A494 CY40 |

| Inconel® 625 | N06625 | 2.4856 | B564 N06625 | A494 CW 6MC |

| Hastelloy® B2 | N10665 | 2.4617 | B564 N10665 | A494 N 12MV |

| Hastelloy® B3 | N10675 | 2.46 | B564 N10675 | |

| Hastelloy® C22 | N06022 | 2.4602 | B574 N06022 | A494 CX2MW |

| Hastelloy® C276 | N10276 | 2.4819 | B564 N10276 | |

| Hastelloy® C4 | N06455 | 2.461 | B574 N06455 | |

| Titanium GR. 1 | R50250 | 3.7025 | B381 F1 | B367 C1 |

| Titanium GR. 2 | R50400 | 3.7035 | B381 F2 | B367 C2 |

| Titanium GR. 3 | R50550 | 3.7055 | B381 F3 | B367 C3 |

| Titanium GR. 5 | R56400 | 3.7165 | B381 F5 | B367 C5 |

| Titanium GR. 7 | R52400 | 3.7235 | B381 F7 | B367 C7 |

| Titanium GR. 12 | R53400 | 3.7225 | B381 F12 | B367 C12 |

| Zirconium® 702 | R60702 | B493 R60702 | ||

| Zirconium® 705 | R60705 | B493 R60705 |